How to scale-up your Filling line? As we know from our own brewery, The Moersleutel, growing your brand comes with various challenges.

Menu

Sluiten

- Our machines

Machines

Preparation

Conveyors

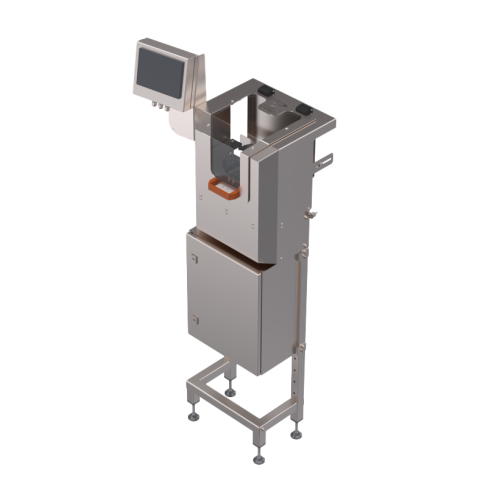

Process quality

- Services

- About

About Zomerdijk Engineering

→ - Blog

Blog

Discover how Zomerdijk Engineering collaborated with the renowned Dutch craft brewery, Jopen. Learn about Jopen transitioning to can packaging

- Contact

- Get a quote

Sluiten

- Our machines

Machines

Preparation

Conveyors

Process quality

- Services

- About

About Zomerdijk Engineering

→ - Blog

Blog

How to scale-up your Filling line? As we know from our own brewery, The Moersleutel, growing your brand comes with various challenges.

Discover how Zomerdijk Engineering collaborated with the renowned Dutch craft brewery, Jopen. Learn about Jopen transitioning to can packaging

- Contact

- Get a quote