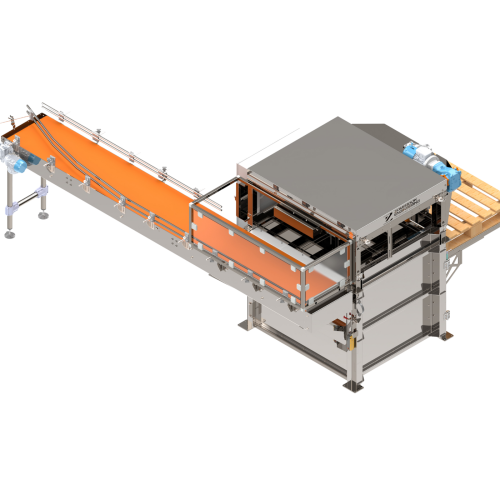

When it comes to optimizing the efficiency and productivity of your filling line, selecting the right depalletizer is an important decision.

Menu

Sluiten

- Our machines

Machines

Preparation

Conveyors

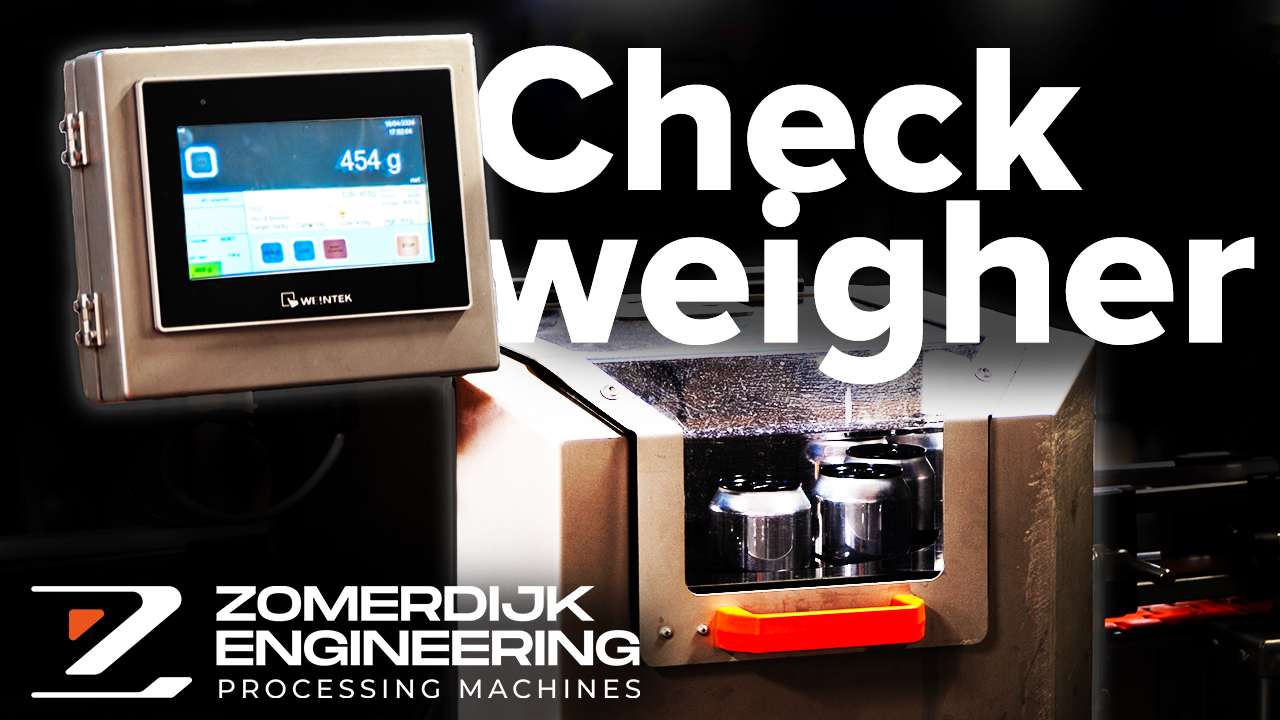

Process quality

- Services

- About

About Zomerdijk Engineering

→ - Blog

Blog

Update on the Automatic Case packer Start of the assembly After two years of engineering, we have started the assembly of the

- Contact

- Get a quote

Sluiten

- Our machines

Machines

Preparation

Conveyors

Process quality

- Services

- About

About Zomerdijk Engineering

→ - Blog

Blog

When it comes to optimizing the efficiency and productivity of your filling line, selecting the right depalletizer is an important decision.

Update on the Automatic Case packer Start of the assembly After two years of engineering, we have started the assembly of the

- Contact

- Get a quote